While hydraulic fittings and couplers may not be the most attention-grabbing products, they play a crucial role in maintaining the safety and efficiency of your hydraulic system. Choosing the right hydraulic fitting or coupler is vital, and with so many types available, it can be a challenge to identify the best fitting for your specific application

Hydraulic fittings are available in hundreds of configurations – in fact, there are too many types to cover in a single article. That’s why for the purposes of this blog post, we will focus on those most relevant to users of hydraulic tools; such as cylinders, cutters, and torque wrenches. We will look at the different types of fittings and couplers, what can go wrong, and things to consider when making your selection.

What are hydraulic fittings?

If you’re new to hydraulics, let’s define what we mean by a fitting. Simply put, hydraulic fittings connect hoses and pipes to other system components such as tools, valves, and pumps. If you use Enerpac hydraulic tools the most common types to be aware of are:

What makes a good hydraulic fitting?

Essentially, a good hydraulic fitting is one that’s appropriate for the specific application. This means choosing the right pressure rating, material, diameter, thread/connection type, and size.

A fitting should be easy to install and remove and should not require specialized tools or excessive force. If you’re choosing a coupler and your main priorities are a quick connection with minimal oil spillage it may be worthwhile paying extra for a flat face push-fit coupler.

Also, if the coupler doesn’t come supplied with a protective dust cap be sure to get one – especially if you work at dirty industrial/construction job sites.

What makes hydraulic fittings and couplers fail?

When used correctly, hydraulic fittings and couplers are unlikely to fail, but its worth taking extra care to avoid the following:

Improper installation: A poorly installed fitting can lead to leaks or even the complete failure of a whole hydraulic system. Over-tightening fittings beyond the recommended torque can cause damage to the fitting, leading to leaks. Don’t be tempted to use tools for couplers designed to be tightened by hand. In addition, if a coupler is not properly aligned with the hydraulic fitting this may also create stress and a risk of fatigue or damage.

Contamination: If dirt, dust, or other contaminants get into the hydraulic fluid, they can clog the coupler and prevent it from functioning properly. This is more of a potential issue for tool users out in the field and less so for factory-based hydraulic work-holding situations.

Impact damage: Physical damage to a coupler can cause it to become deformed, which can prevent it from operating correctly.

Vibration: Vibration over extended periods can cause fittings to loosen over time, leading to leaks or failure. Vibration can be caused by hydraulic pumps and cavitation within the hydraulic fluid.

Over-pressurization: If the pressure in the hydraulic system rises higher than what the coupler is designed to handle this may cause it to fail.

Corrosion: Over time, in harsh conditions, hydraulic fittings can corrode due to exposure to moisture, chemicals, or other environmental factors. This has the potential to weaken the fittings which could lead to leakage or failure.

Fatigue: Repeated cycles of pressure and stress can cause fatigue in the fittings, leading to cracks and failure.

Wear and tear: Over time, fittings and couplers that include seals may become worn and therefore lose their ability to maintain a tight seal.

Selecting Hydraulic Fittings: 5 Key Considerations

Pressure – Check the maximum rated pressure needed. Components used with hydraulic tools are classified as high-pressure and typically rated for either 5000 or 10000 psi (350 or 700 bar). The fittings supplier should make this clear in their catalogs or on their website.

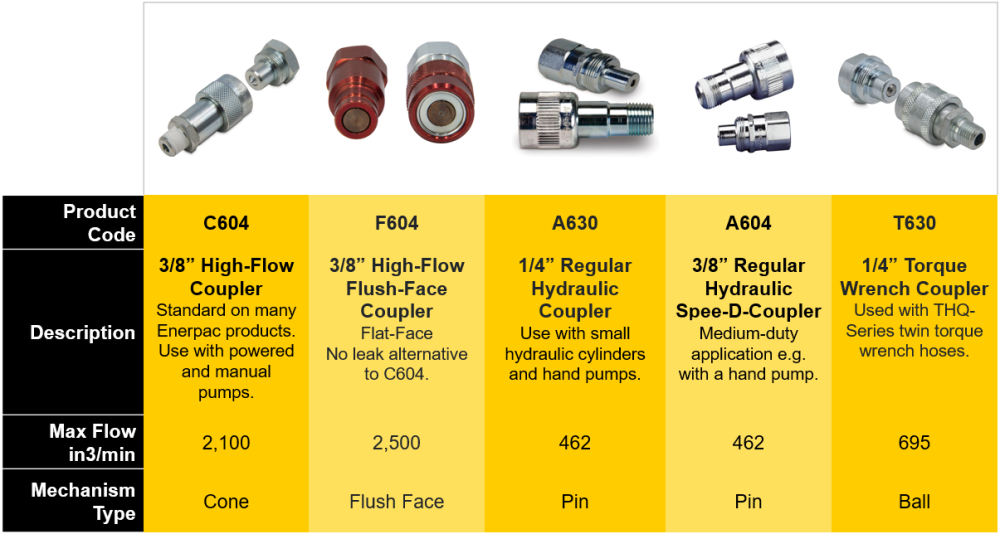

Flow Rate – The type and size of the tool will determine the flow needed. If you need a high-flow coupler, consider the Enerpac C (cone) type or F (flat face) type. These allow for up to 4 times more flow than many standard couplers.

Thread Type – These vary by region throughout the world, so make sure your fittings, tools, and hoses are compatible. If they’re not, an adapter or reducer may be available to solve the issue. Buying your hydraulic tools and hose connectors from a single manufacturer will help to avoid incompatibility issues.

Coupler Connection Type – Choose between the common type with a threaded sleeve to hand tighten, and “push to fit” flat face types that save time and minimize oil loss and spillage.

Material – The material of the fitting can influence its pressure rating and ability to withstand harsh and corrosive working environments. Also, bear in mind it’s not good practice to mix some metal types because of potential galvanic corrosion.

What are the standard sizes?

Hydraulic fittings are available in many different sizes. However, if you are using Enerpac hydraulic tools the standard fittings and couplers will most likely be ¼” or 3/8”, with NPTF or SAE thread types.

Identifying Hydraulic Fittings

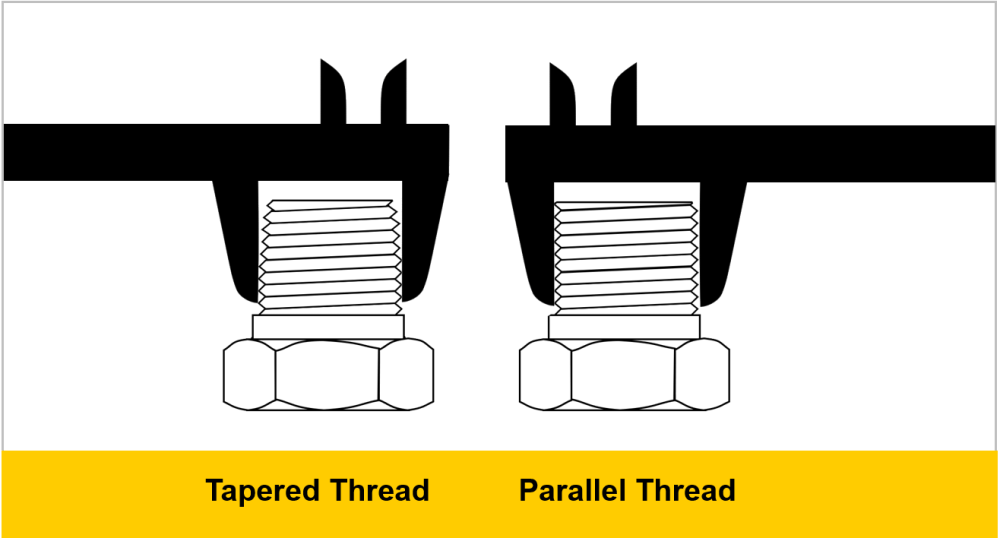

A visual check of the type and size of the fitting is the first obvious step. However, when it comes to threads, at first glance these can all look the same. Fortunately, there are ways you can narrow down the possibilities. See more on the Parker blog here.

First, look at the fitting from the side view to see if the thread is tapered or parallel. A tapered thread will get smaller in diameter towards the end. If you cannot tell this immediately, try using vernier calipers. The next thing you can do is check the thread pitch with a pitch gauge.

Finally, determine the nominal size by measuring the outside diameter or checking against a thread profile gauge. If you have a selection of known threaded fittings handy, checking to see how well these connect can also help.

Types of Hydraulic Couplers

A hydraulic coupler makes quick connections to your hydraulic system and typically includes male and female halves which can be connected by hand. For example, the C-Series Coupler is the standard on most Enerpac pumps and cylinders up to 10,000 psi (700 bar). You can buy them as a complete set or individually as male and female halves. Where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy to make a secure connection.

Standard Regular Couplers

Common sizes of this type are ¼” – for use with small hydraulic cylinders and pumps. Some larger tools and medium-duty applications will most likely need a larger 3/8” coupler. Whichever you choose, the maximum flow capacity will be around 462 in3/min.

High Flow Couplers

These are available in cone or flat face types. The cone type is less prone to back pressure than other types such as ball-style couplers. On the downside, they leak a little oil when disconnecting. The alternative solution is the more expensive flat face type click fit type, which is very much leak free.

Flat Face Hydraulic Couplers

These high-flow couplers feature a quick push to connect operation and also prevent spillage of hydraulic fluid. Although these are a simple push-fit design, users should not be concerned about their safety as they are recognized by the Hydraulic Tool Manufacturers Association for safety and performance. F-Series Flush Face couplers from Enerpac are 3/8” and allow a generous flow capacity of 2000in3/min (40 l/min).

Torque Wrench Couplers

As the name implies, these are for use with hydraulic torque wrenches such as the Enerpac S-, W-, RSL-, DSX-, and HMT-Series. These are used with THQ-Series twin torque wrench hoses. They are usually ¼” unlike the large 3/8” couplers used for hydraulic cylinders and pumps.

Types of Fittings

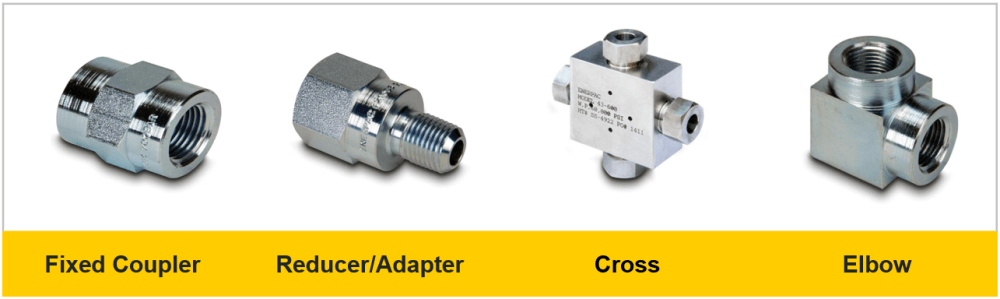

Adapters and Reducers

Hydraulic adapter fittings are used to connect hydraulic hoses, tubes, and pipes of different sizes and types. Example uses are to connect different thread sizes or connector types, for example, from male to female threads or from NPT (National Pipe Thread) threads to SAE #4 (Society of Automotive Engineers).

Fixed Couplings

A fixed coupling simply attaches two same-sized threaded components together using female threads. A hexagonal section in the center enables the coupling to be held while attaching.

Elbow, Tee, and Cross-Fittings

Other fixed fittings for more permanent connections. Used for changing flow direction or adding an extra connection.

Dust Caps for Hydraulic Fittings and Couplers

Dust caps for hydraulic couplers prevent dirt from entering the system which could cause the coupler to fail, or lead to premature wear of internal components. Types include push-fit plastic dust caps, (sometimes with a 2-in-1 configuration for both male and female haves), and also metal screw-on caps. Both types include a retaining strap or chain to keep it attached to the tool or hose fitting.

Coupler Bleed Tools

Considering the high pressures involved when using hydraulic tools, the risks of injury caused by projectile parts and under-skin hydraulic fluid injections are high if couplers are incorrectly used. A coupler bleed tool like the CT604 relieves hydraulic back pressure by safely bleeding the high-flow hydraulic coupler. The CT-604 is compatible with C Series couplers and works by slow hand rotation of the knob. This applies a force onto the ball or cone inside the coupler. Once the ball or cone is pushed from its seat the pressure is relieved. Read more about safe depressurization in this blog post.

Where to Buy Hydraulic Fittings and Couplers

If you are looking for hydraulic fittings to use with Enerpac tools you can get these from your nearest Enerpac distributor. If you’re based in the United States, you can buy hydraulic fittings online directly from Enerpac.

Conclusion

In summary, a ‘good’ hydraulic fitting is one that matches the application, with the most important selection criteria being operating pressure, thread/connector compatibility, flow rate, and material compatibility. If you select fittings and couplers from the same manufacturer or distributor that you got your hydraulic tools from this should be easier than shopping around.

Most importantly, to ensure safety, you must install and disassemble your fittings correctly, which means using the specified torque for threaded fittings and always depressurizing the system before removing any coupler or fitting.